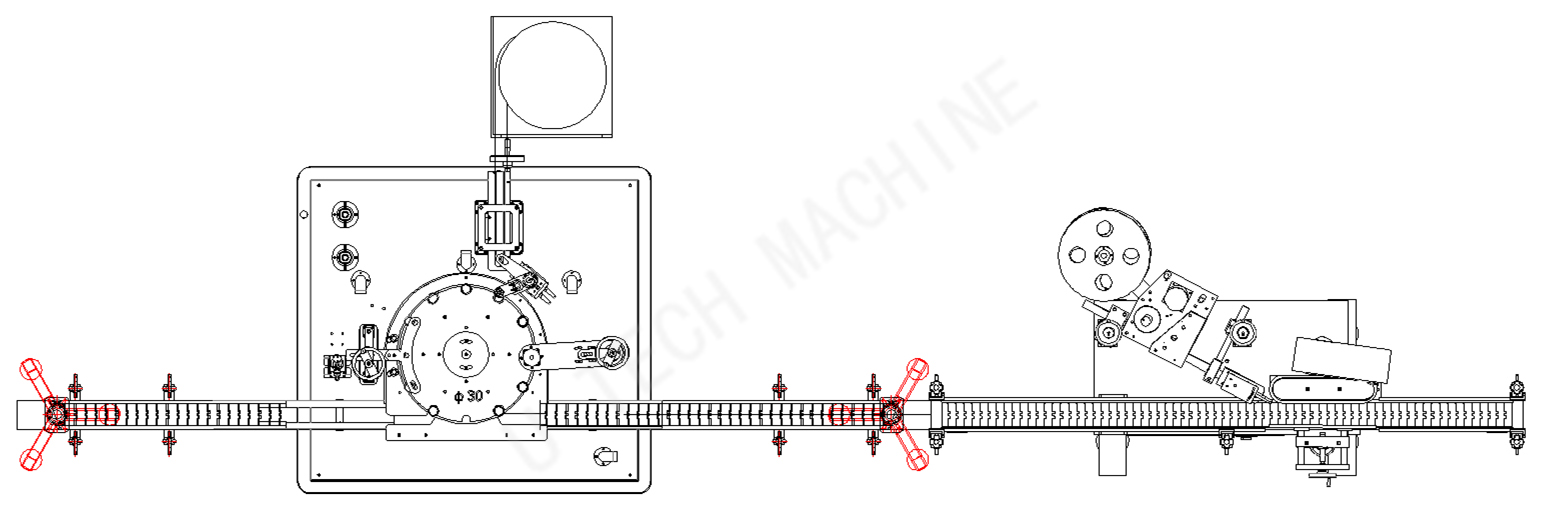

Name: filling heads

Brand: U Tech

Original: Jiangsu China

gravity filling with holding bottle neck; the special back flow type of the filling valve can avoid leakage after filling and also control liquid level accurately.

| Availability: | |

|---|---|

| Quantity: | |

| Containers and Specifications | ||||

| Project Name:Automatic Oil Filling Machine | Oil and Fat Products | |||

| Bottle Material | Bottle Shape | Filling Range | Filling Heads | Production Capacity |

| PET / PP / PE / Glass / Metal | Round / Square / Unique Shape | 200ml-6000ml | 24 | 6000-8000bph |

| Filling Valve | Each filling valve is controled by servo motor ,realizing segmented high-and low-speed control ; vacuum resorption devices without leakage. | |||

| Cap closing method | applicability for both crowning and capping, mechanical instant sealing or servocontrolled sealing | |||

| Bottle components | rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps | |||

| Filling precision | limit deviation: ±2-3g standard deviation: 1.5 | |||

| User Ambient Conditions | Temperature:10~40℃;Humidity:No dew | |||

| User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | |||

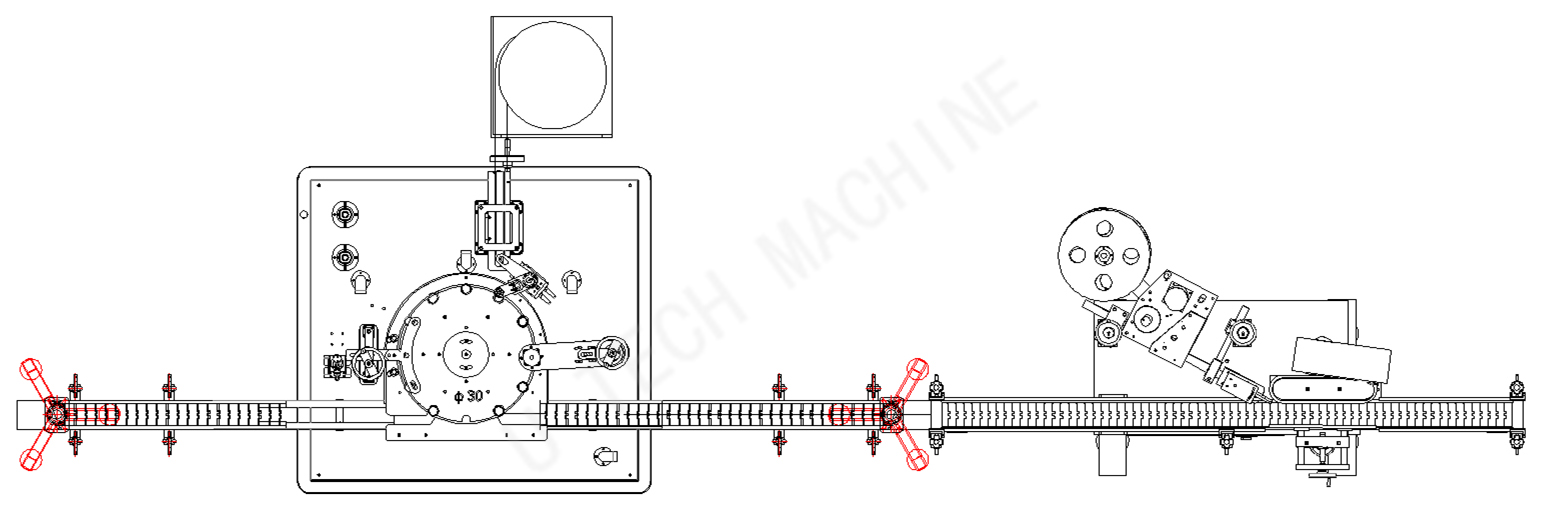

Name: filling heads

Brand: U Tech

Original: Jiangsu China

gravity filling with holding bottle neck; the special back flow type of the filling valve can avoid leakage after filling and also control liquid level accurately.

Name: capping heads

Brand: U Tech

Original: Jiangsu China

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

1. Touch screen operation interface;

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash;

3. The filling accuracy can reach +/-1%;

4. The flling cylinder is ground, unique flling valve design, no leakage;

5. With no bottle no flling and automatic bottle stop function;

6. Design different positioning devices according to the actual situation of the bottle;

7. The equipment is easy to clean, can be disassemble without tools, it can also be cleaned online or high temperature sterilization;

8. PLC programmable control use Japan Mitsubishi;

9. Frequency converter adopts France Schneider;

10. Pneumatic components adopt Taiwan Airtac;

11. Material contact parts are made of SUS304# stainless steel;

12. The equipment meets the hygiene and safety standards. The user can choose the glass protective cover.

| S/N | Name | Brand | Country |

| 1 | Main motor | ABB | Switzerland |

| 2 | Inverter | MITSUBISHI | Japan |

| 3 | PLC | OMRON | Japan |

| 4 | Touch screen | MITSUBISHI | Japan |

| 5 | Contactor | SCHNEIDER | France |

| 6 | Thermo- relay | SCHNEIDER | France |

| 7 | Air-break switch | SCHNEIDER | France |

| 8 | Proximity switch | TURCK | USA |

| 9 | Photoelectric switch | BANNER | USA |

| 10 | Air circuit system | SMC | Japan |

| 11 | Water pump | Southern | China |

| Containers and Specifications | ||||

| Project Name:Automatic Oil Filling Machine | Oil and Fat Products | |||

| Bottle Material | Bottle Shape | Filling Range | Filling Heads | Production Capacity |

| PET / PP / PE / Glass / Metal | Round / Square / Unique Shape | 200ml-6000ml | 24 | 6000-8000bph |

| Filling Valve | Each filling valve is controled by servo motor ,realizing segmented high-and low-speed control ; vacuum resorption devices without leakage. | |||

| Cap closing method | applicability for both crowning and capping, mechanical instant sealing or servocontrolled sealing | |||

| Bottle components | rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps | |||

| Filling precision | limit deviation: ±2-3g standard deviation: 1.5 | |||

| User Ambient Conditions | Temperature:10~40℃;Humidity:No dew | |||

| User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | |||

Name: filling heads

Brand: U Tech

Original: Jiangsu China

gravity filling with holding bottle neck; the special back flow type of the filling valve can avoid leakage after filling and also control liquid level accurately.

Name: capping heads

Brand: U Tech

Original: Jiangsu China

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

1. Touch screen operation interface;

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash;

3. The filling accuracy can reach +/-1%;

4. The flling cylinder is ground, unique flling valve design, no leakage;

5. With no bottle no flling and automatic bottle stop function;

6. Design different positioning devices according to the actual situation of the bottle;

7. The equipment is easy to clean, can be disassemble without tools, it can also be cleaned online or high temperature sterilization;

8. PLC programmable control use Japan Mitsubishi;

9. Frequency converter adopts France Schneider;

10. Pneumatic components adopt Taiwan Airtac;

11. Material contact parts are made of SUS304# stainless steel;

12. The equipment meets the hygiene and safety standards. The user can choose the glass protective cover.

| S/N | Name | Brand | Country |

| 1 | Main motor | ABB | Switzerland |

| 2 | Inverter | MITSUBISHI | Japan |

| 3 | PLC | OMRON | Japan |

| 4 | Touch screen | MITSUBISHI | Japan |

| 5 | Contactor | SCHNEIDER | France |

| 6 | Thermo- relay | SCHNEIDER | France |

| 7 | Air-break switch | SCHNEIDER | France |

| 8 | Proximity switch | TURCK | USA |

| 9 | Photoelectric switch | BANNER | USA |

| 10 | Air circuit system | SMC | Japan |

| 11 | Water pump | Southern | China |