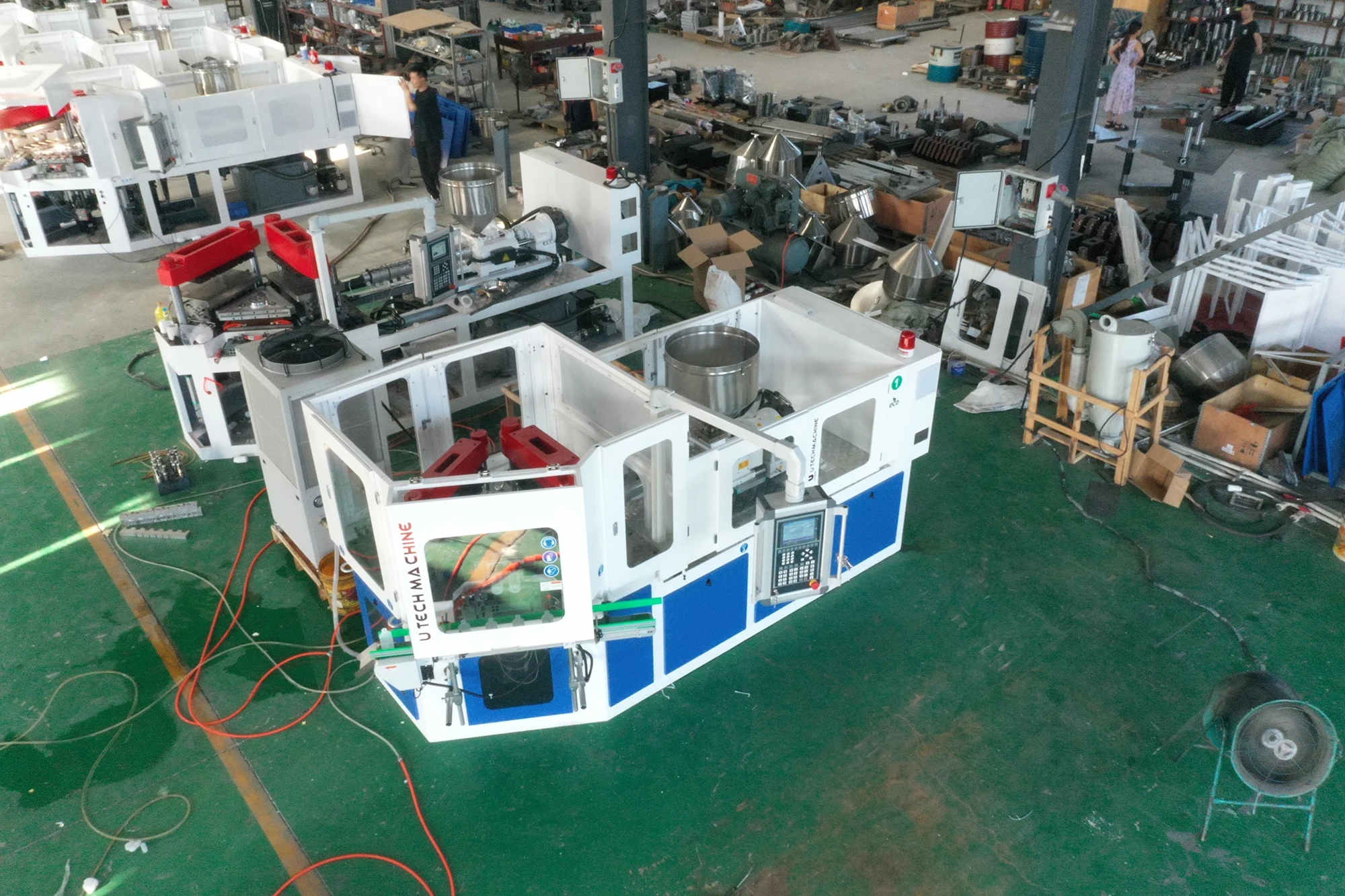

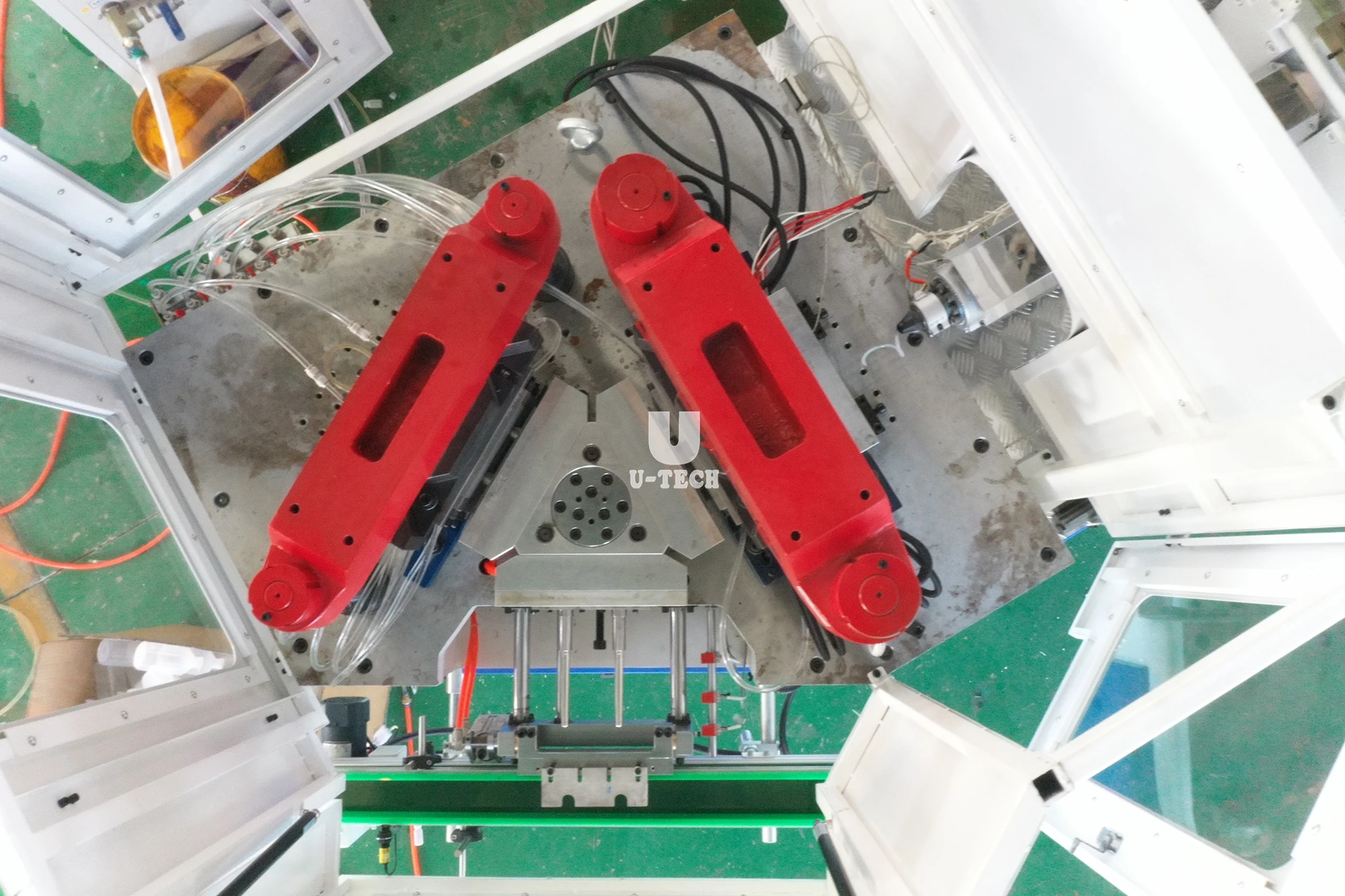

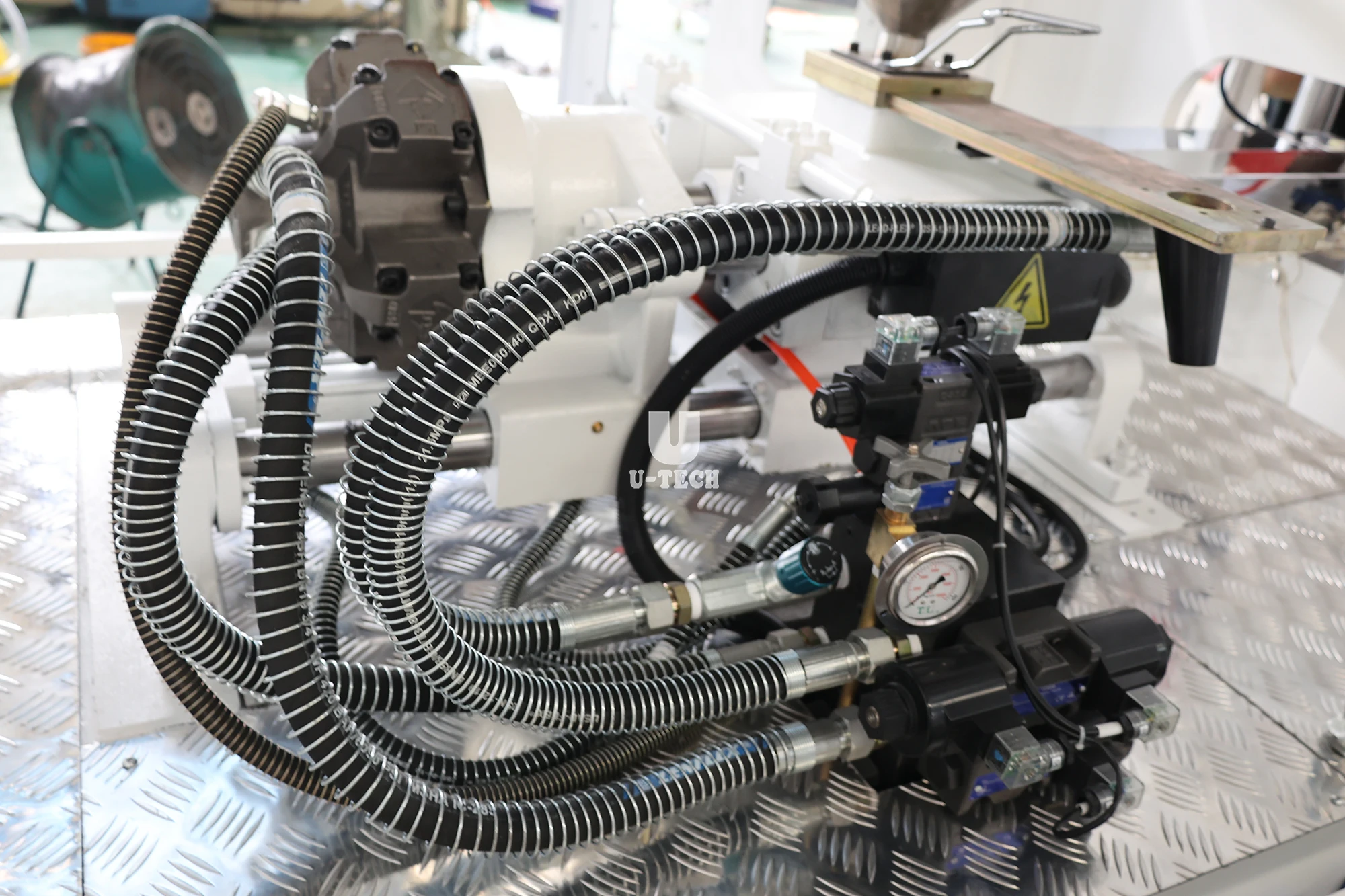

The BST series extrusion blow molding machine is used to produce all kinds of the hollow plastic containers for foods, toys, beverages, medicines, chemical products, pesticides, detergents, etc with material of PE,PP,PVC from 5ml to 20L,such as water

bottles,milk bottles,medical bottles,oil bottles,plastic balls,cosmetic bottles,lubricant bottles,plastic containers.

Zhangjiagang U Tech Machine Co.,Ltd

Professional manufacturer of beverage filling machine

E-mail:

Phone/Whatsapp:

+86-13962296786

- Home

- Products

- Water Filling Machine

- Carbonated Beverage Filling Machine

- Juice Tea Hot Filling Machine

- Glass Bottle Filling Machine

- Oil Filling Machine

- Can Filling Machine

- 5L/5Gallon water filling machine

- Piston filling machine

- Pretreatment System

- Labeling Machine

- Packing Machine

- Extrusion Blow Moulding Machine

- Jerrycan Blow Moulding Machine

- Plastic Bottle Blow Moulding Machine

- Drum & Barrels Blow Moulding Machine

- Toy & Playgound Parts Blow Moulding Machine

- Pallet ,Board &IBC Tank Blow Moulding Machine

- Traffic Barrer Blow Moulding Machine

- Automotive Parts Blow Moulding Machine

- Irregular-shaped products Blow Moulding Machine

- PET Bottle Blow Moulding Machine

- Injection Moulding Machine

- Spare Part

- Other auxiliary machine

- Beverage Filling Solutions

- Video

- Why Choose Us

- About Us

- Contact Us