Description

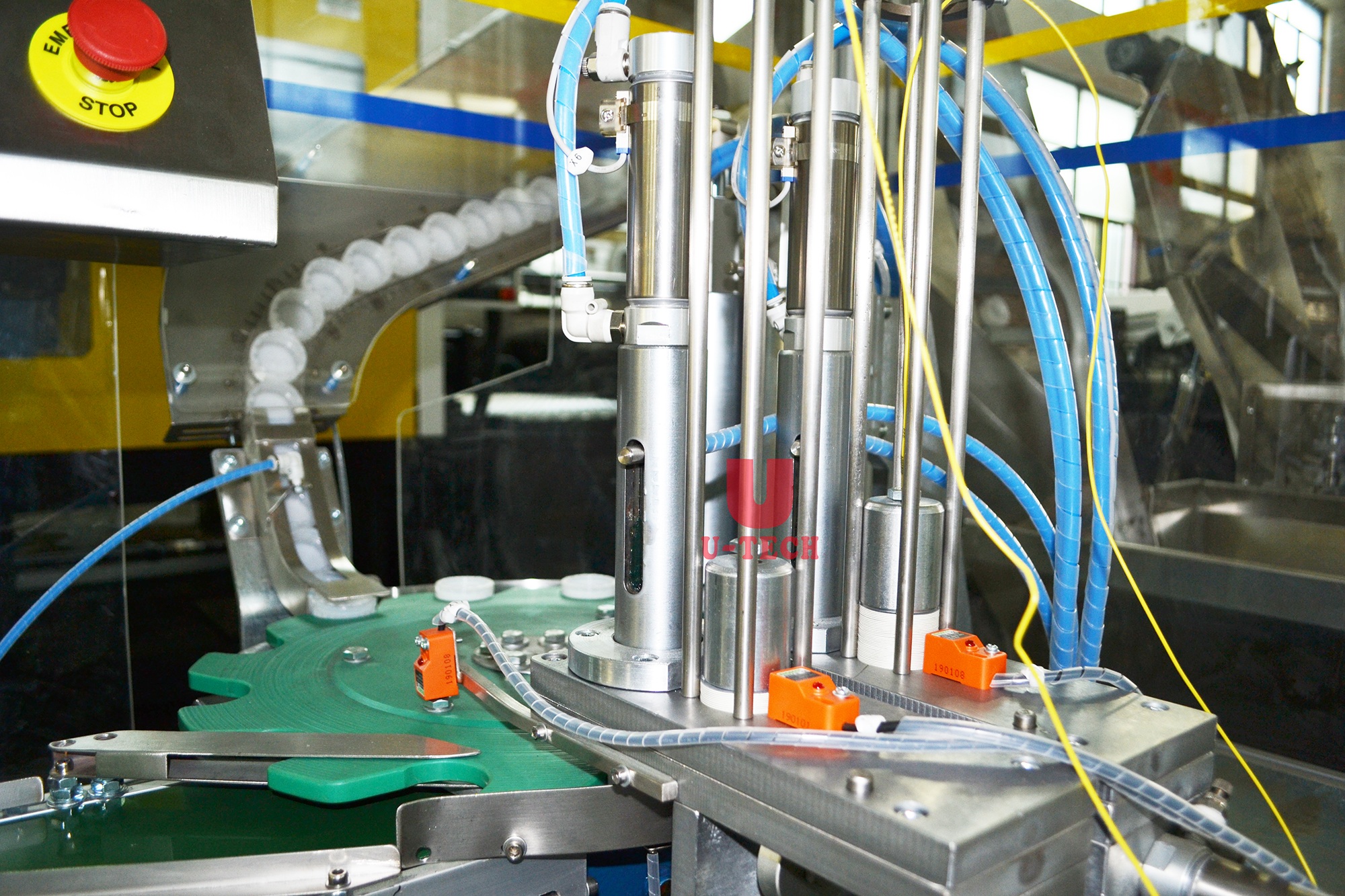

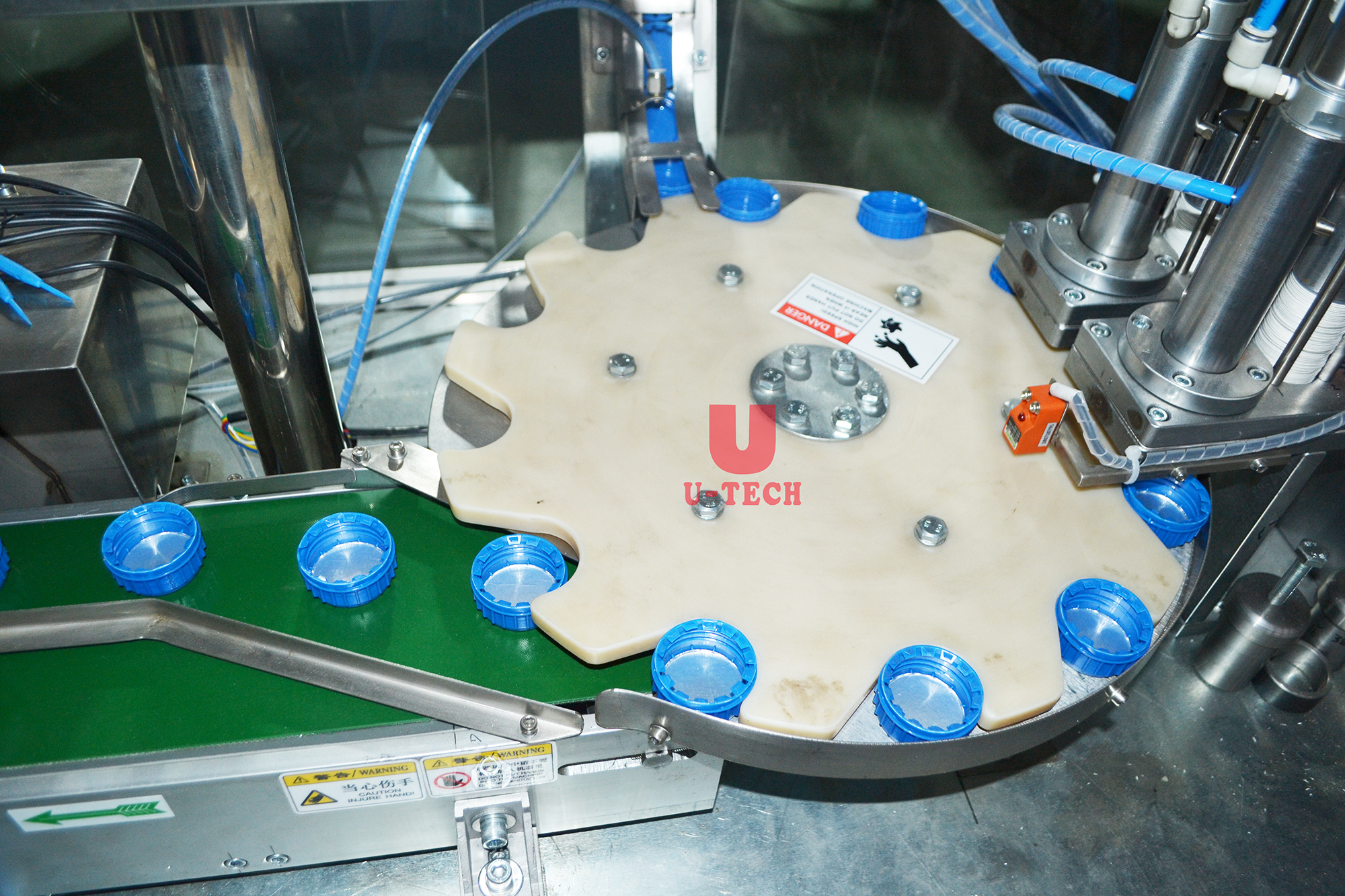

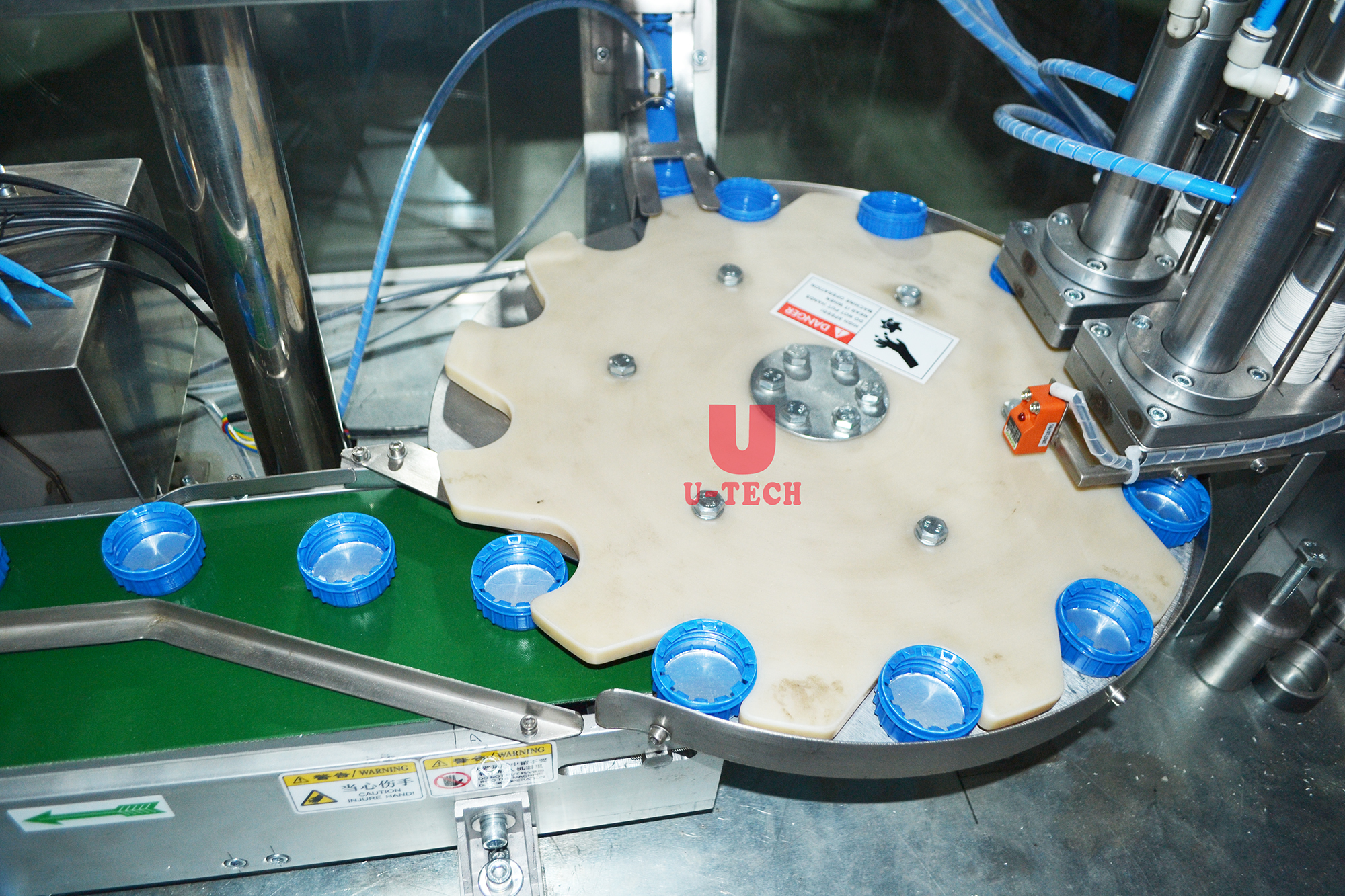

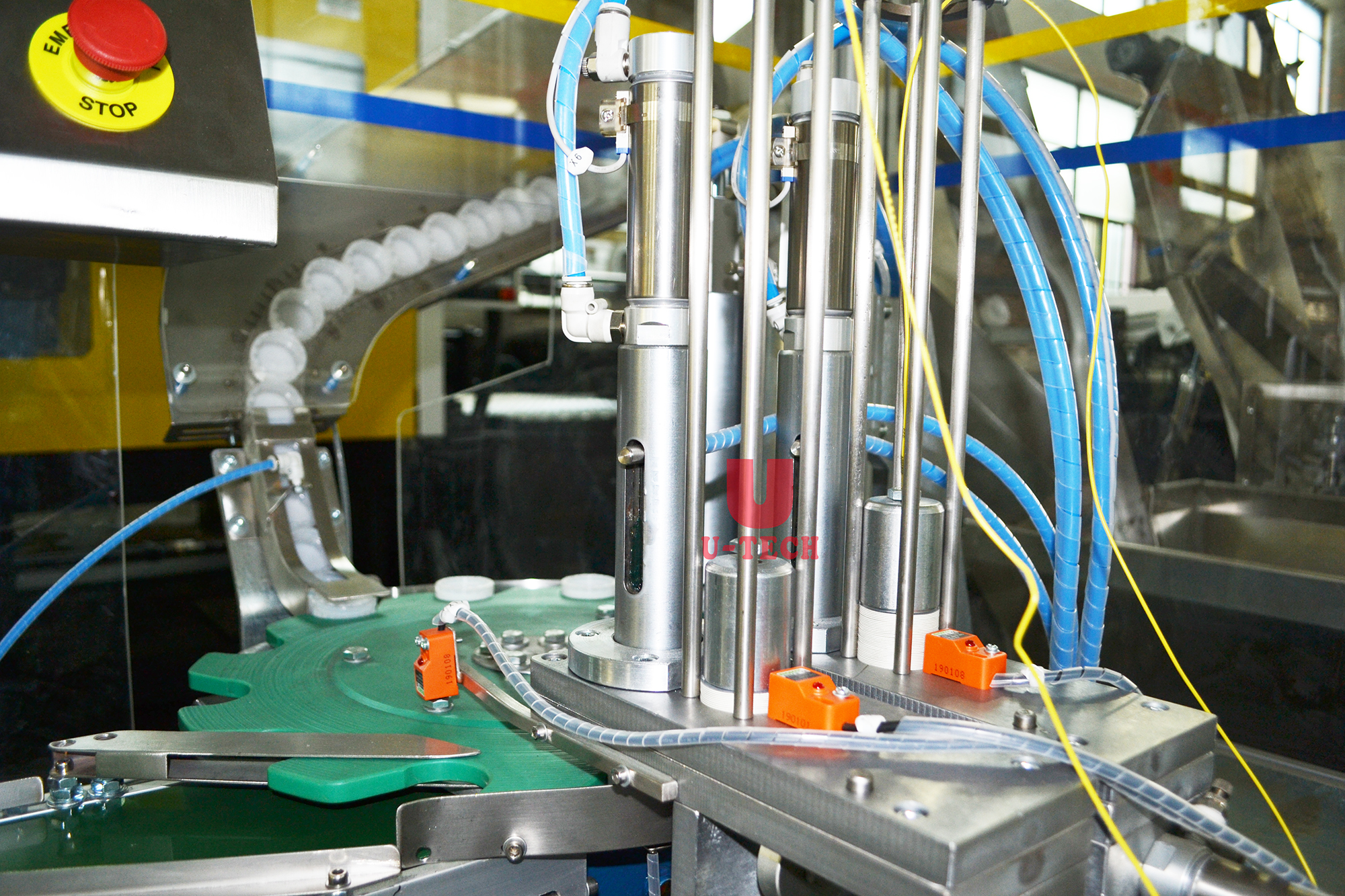

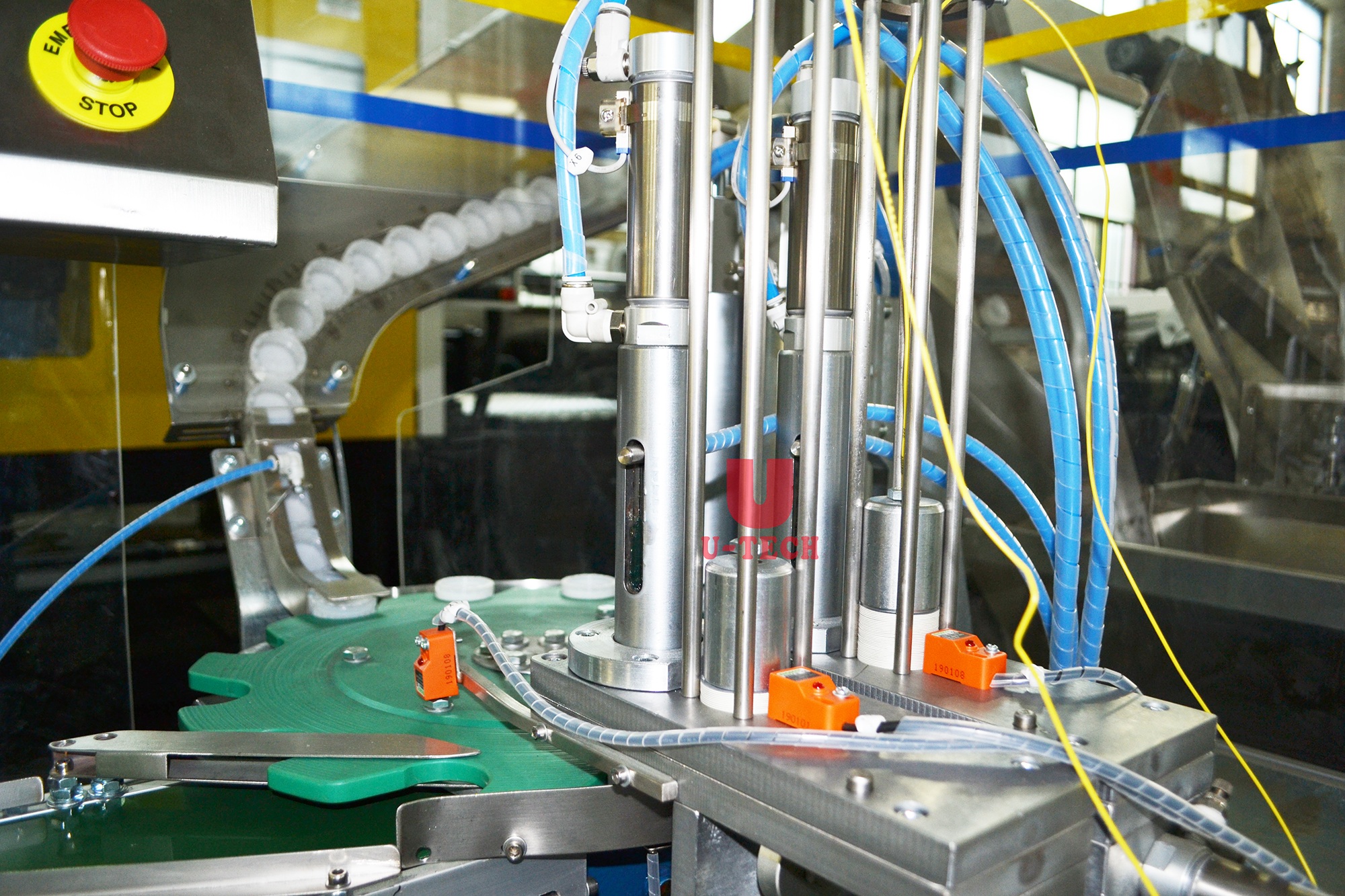

Automatic cap lining machine , which can cut the foil roll into liner and insert the liner into cap at the same time, with the speed up to 120 pieces/min, avoiding the manual pollution and improving the product efficiency as well.

It has ability to run different size cap. The machine’s operation is fully automatic, highlighted by Detal programmable logic controller(PLC), a touch screen operator interface terminal, missing foil cap director and alarm system.

this cap lining machine is helpful to the cap production, it will enduremany years of consitent production.

The main feature of equipment

1. including one set host equipment, one set pulp liner Locate and inserting equipment,one set pulp roll sending machine ,one set wasted pulp roll colloecting machine, one cap elevator.

2. one set round cap liner model;

3. PLC system, touch screen operation system.

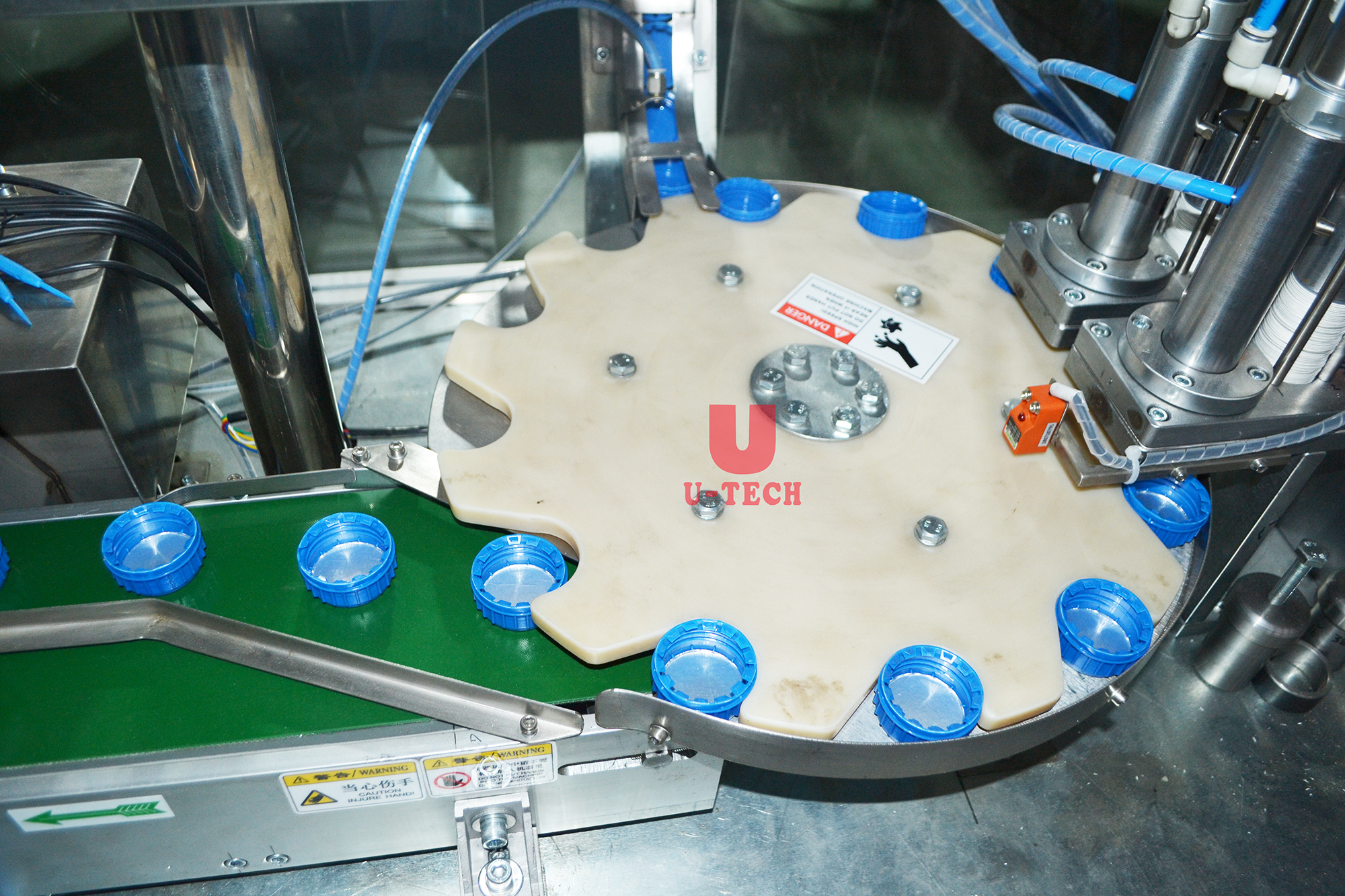

4. automatic cap arranger,automatic Rejection system for improperly caps , which upside down.

5. the turntable locating, cutting and inserting the pulp liner into cap more precisely.

6. the foil roll diameter for foil sending machine: inner diameter is 76mm, outside diameter is no less than 500mm.

7. the length of pulp roll can be adjustable. So it can make sure the inserting job more precisely.

8. high quality and performance. It can work 24 hours per day and no stopping.

9. with counting function and output pre-setting function

10. with the detect function for liner missing and reject the no liner cap (this function is base on the cap colour different from pulp liner colour)

11. system stop and alarm when caps are in short supply

12.safety running: automatically alarm and stop when breakdown occur

13. The work speed is 120 caps per min.

14. Electric Power source :220V,50-60HZ, Single power supply;(also, can be design according to customer requirement)

15. use UL PLC, touch screen, Switching Power Supplier, button.

Machine details