Zhangjiagang U Tech Machine Co.,Ltd

Professional manufacturer of beverage filling machine

E-mail:

Phone/Whatsapp:

+86-13962296786

- Home

- Products

- Water Filling Machine

- Carbonated Beverage Filling Machine

- Juice Tea Hot Filling Machine

- Glass Bottle Filling Machine

- Oil Filling Machine

- Can Filling Machine

- 5L/5Gallon water filling machine

- Piston filling machine

- Pretreatment System

- Labeling Machine

- Packing Machine

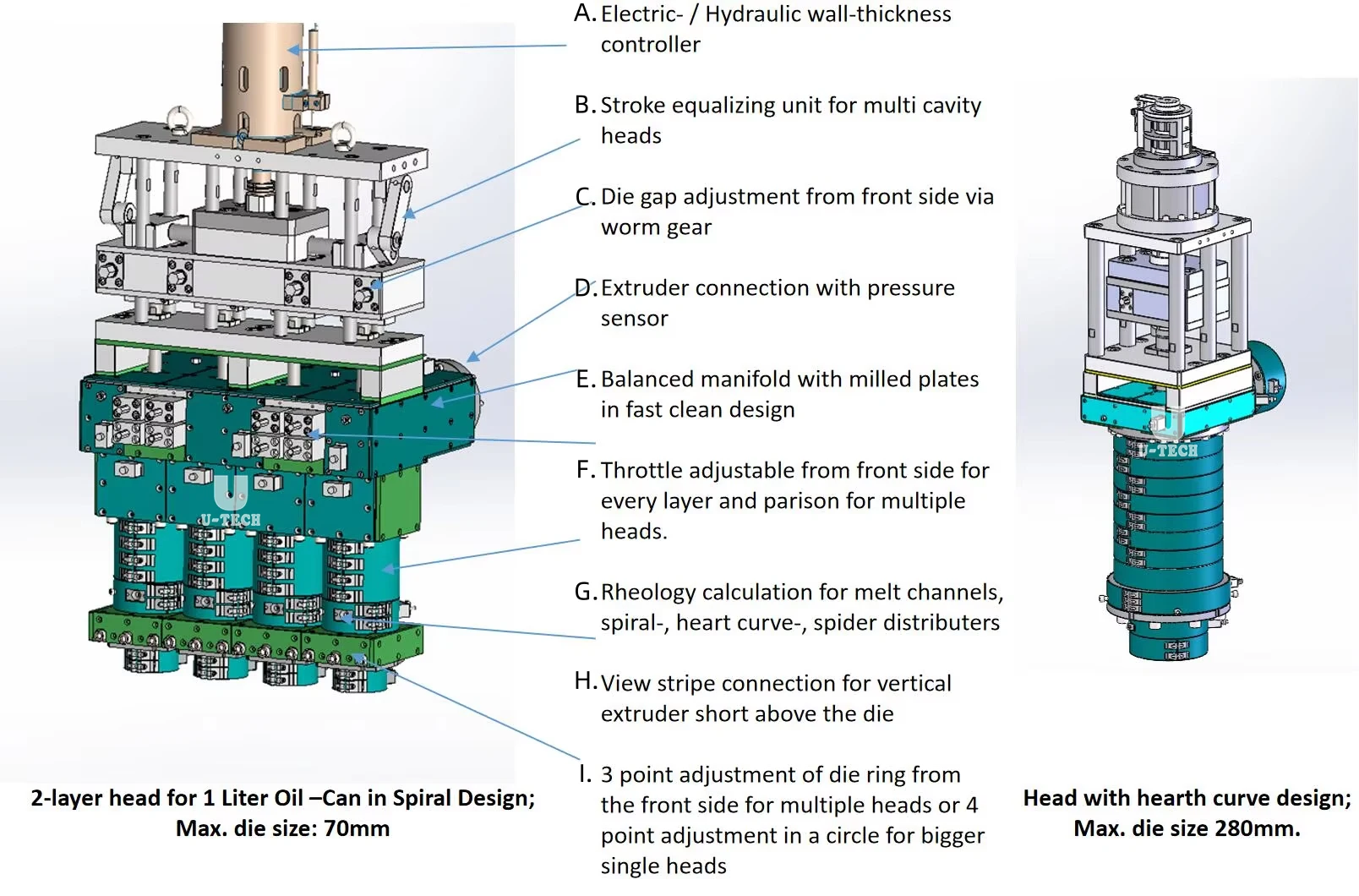

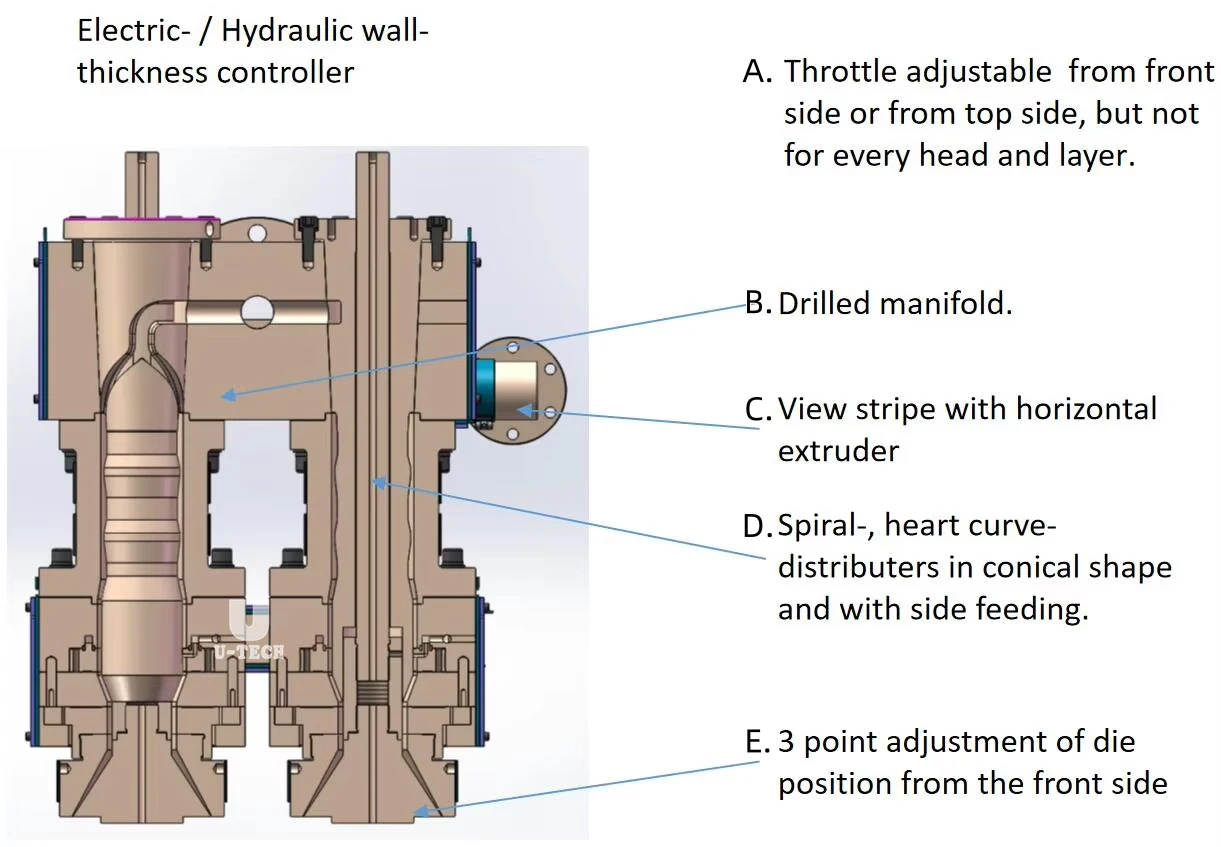

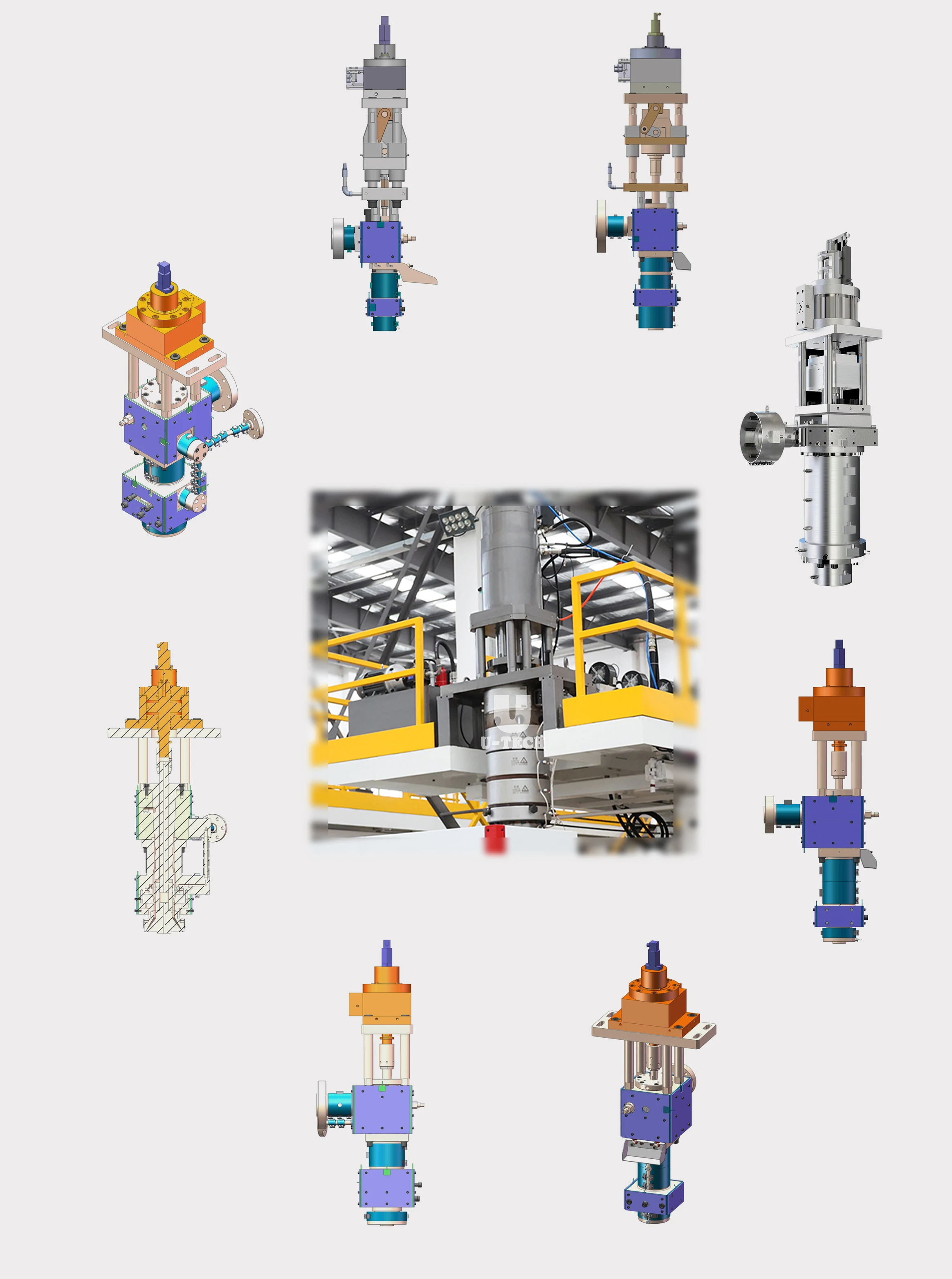

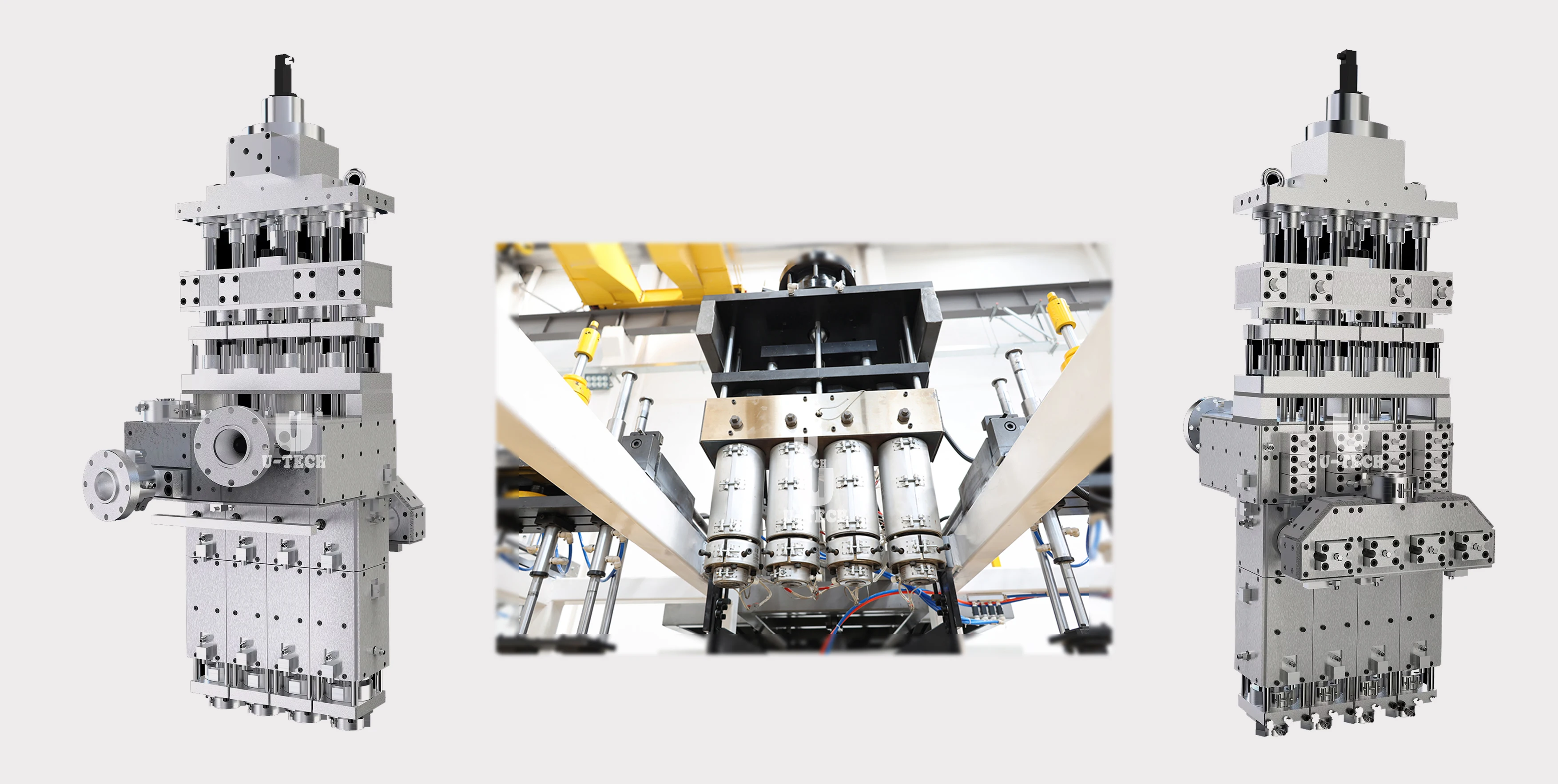

- Extrusion Blow Moulding Machine

- Jerrycan Blow Moulding Machine

- Plastic Bottle Blow Moulding Machine

- Drum & Barrels Blow Moulding Machine

- Toy & Playgound Parts Blow Moulding Machine

- Pallet ,Board &IBC Tank Blow Moulding Machine

- Traffic Barrer Blow Moulding Machine

- Automotive Parts Blow Moulding Machine

- Irregular-shaped products Blow Moulding Machine

- PET Bottle Blow Moulding Machine

- Injection Moulding Machine

- Spare Part

- Other auxiliary machine

- Beverage Filling Solutions

- Video

- Why Choose Us

- About Us

- Contact Us