Product Introduction

This glass bottle filling machine adopts advanced SIEMENS programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectrical inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

Machine Details

Machine Details

Washing part

Into bottle way is air conveyor direct connection with bottle dial.All 304/316 stainless steel washer, water injection design, water level balance, cleaner and less water.

All 304/316 stainless steel gripper with plastic pad to ensure the smallest possibility of bottle collision to protect the bottle is not easy to break.

All 304/316 stainless steel washing pump make the machine more durable.

Filling part

No Bottle No Filling. All 304/316 stainless steel filling pump.

All 304/316 Stainless steel high precision filling nozzle.

All 304/316 stainless steel contact parts and liquid tank, fine polish, no death corner, easy to clean.

Capping part

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping. All 304/316 stainless steel construction

No bottle no capping

Automatic stop when lack of bottle

Capping effect is stable and reliable

Technical Parameters

Model | Washing | Filling | Capping | Capacity(b/h)500ml | Motor power | Overall dimension(mm) |

| heads | heads | heads | (KW) |

| BFGF14-12-5 | 14 | 12 | 5 | 2000bph | 1.5KW | 2100x1400x2500 |

| BFGF18-18-6 | 18 | 18 | 5 | 3000bph | 2.2KW | 2460x1720x2650 |

| BFGF24-24-6 | 24 | 24 | 6 | 4000bph | 3KW | 3100x2100x2650 |

| BFGF32-32-10 | 32 | 32 | 10 | 6000bph | 4KW | 3500x2500x2650 |

| BFGF40-40-10 | 40 | 40 | 10 | 8000bph | 7.5KW | 4600x1800x2650 |

Related Products

Hot melt glue OPP labeling machine

This hot melt glue plastic bottle label applicator is widely suitable for different material of container and label. The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and intergrated operating.

Adhesive labeling machine

The machine can simultaneously achieve two-sided circumferential surface labeling and labeling features to satisfy the flat bottles, square bottles and bottle shaped single-sided and double side labeling, the entire circumference of the cylindrical body,a half weeks labeling, widely used cosmetics industry, daily chemical industry. Optional Tape printer and inkjet printer to achieve the production date printed on the label and batch information to achieve labeling – endowed integration.

Wrap around caser

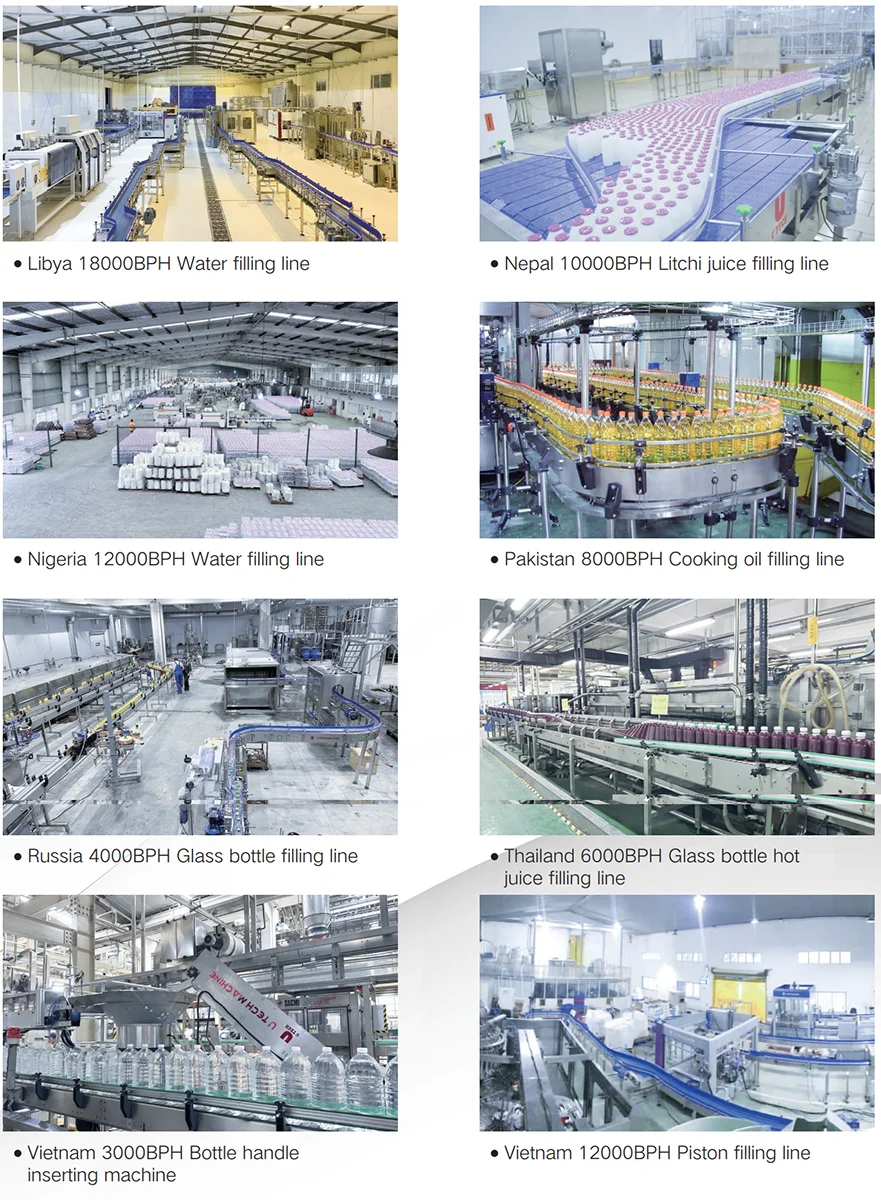

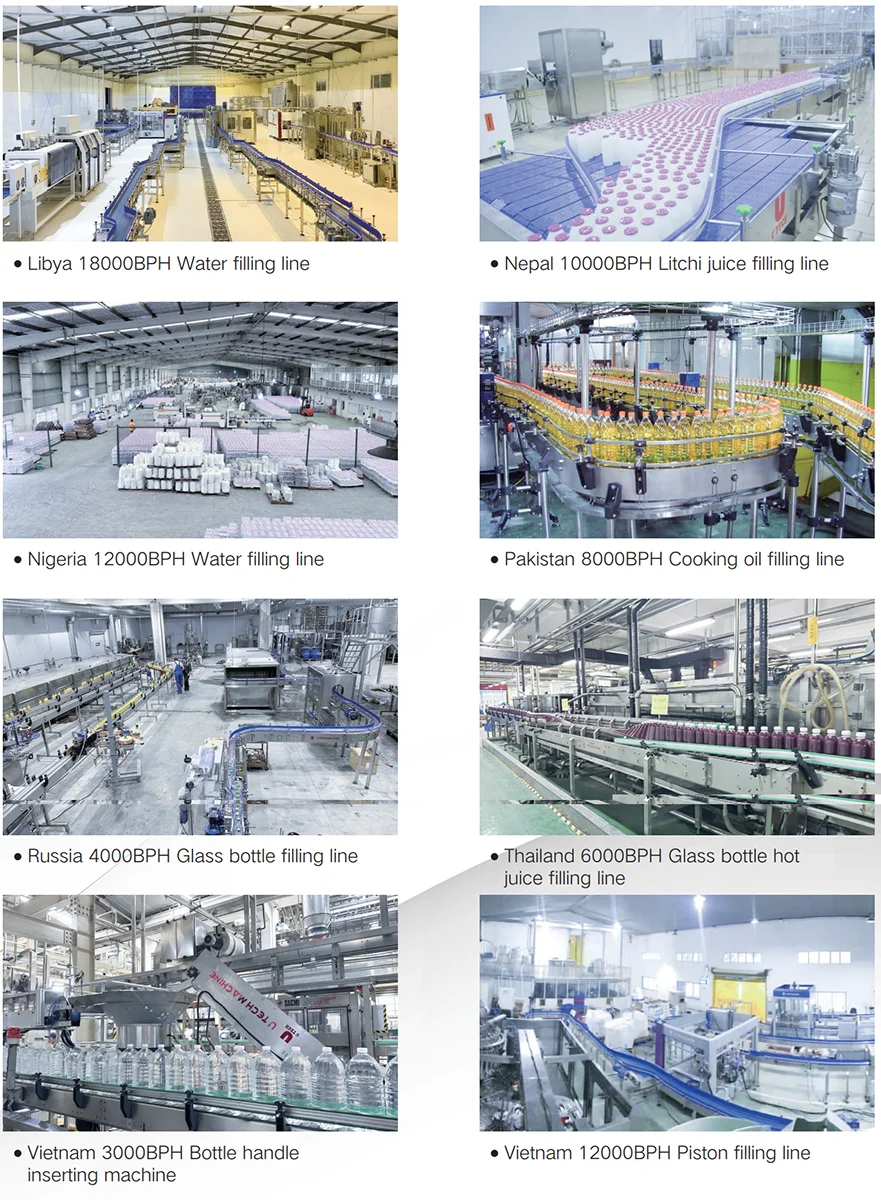

Wrap around caser has high degree of automation,simple operation and strong adaptability.For example,the wrap around caser can be used to die-cut cardboard,nail the box,seal the bottom,box packing,and seal the box at one time,which reduces the equipment and equipment cost,greatly reduce the equipment and raw materials to occupy the space and transport contradictions at all levels.Success Cases

Machine Details

Machine Details