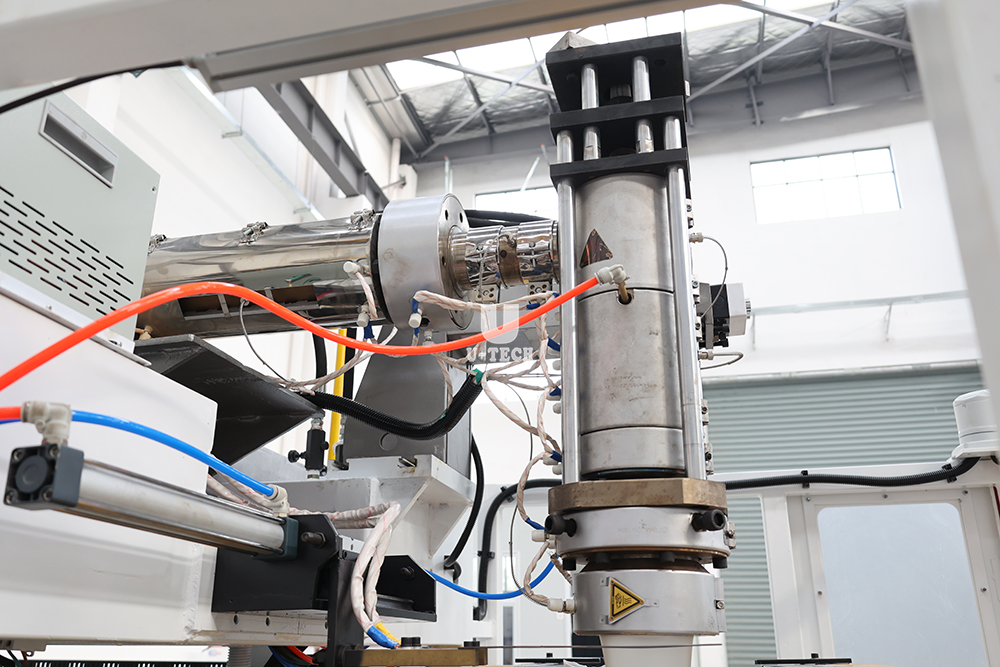

2. Center feeding extrusion, no blind angle, fast color andm aterial changing.

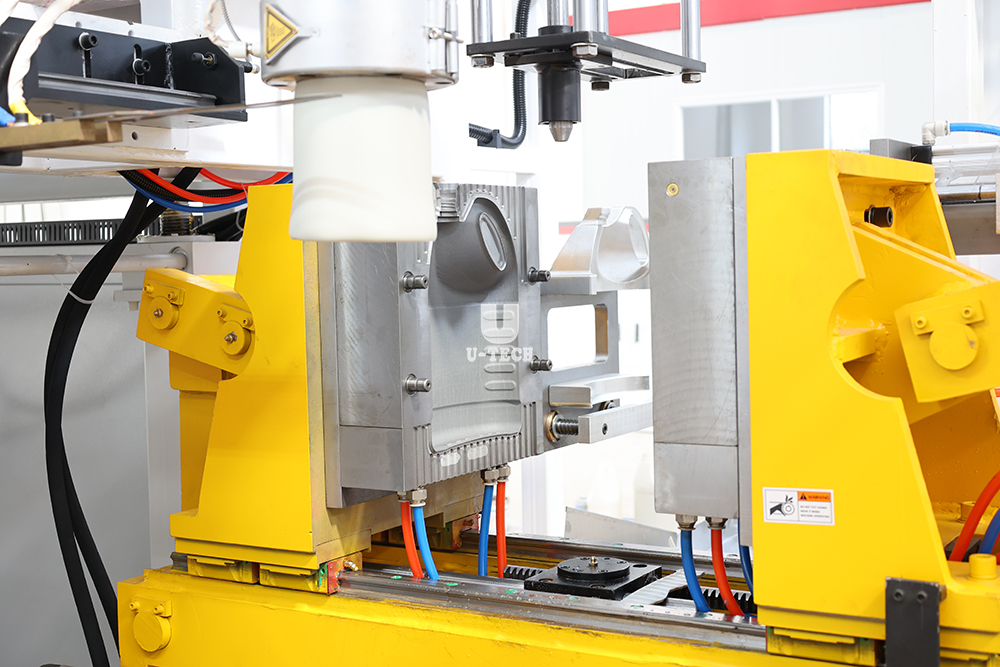

3. Origin from in-house at high precision CNC center.

4. Heating bands evenly distributed to efficiently maximizeplasticizing capacity and avoid material deformation at this critical stage of the extrusion.

4. Heating bands evenly distributed to efficiently maximizeplasticizing capacity and avoid material deformation at this critical stage of the extrusion.