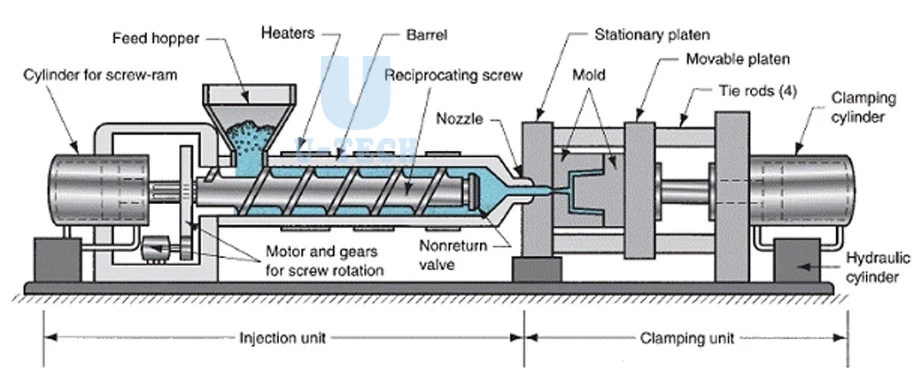

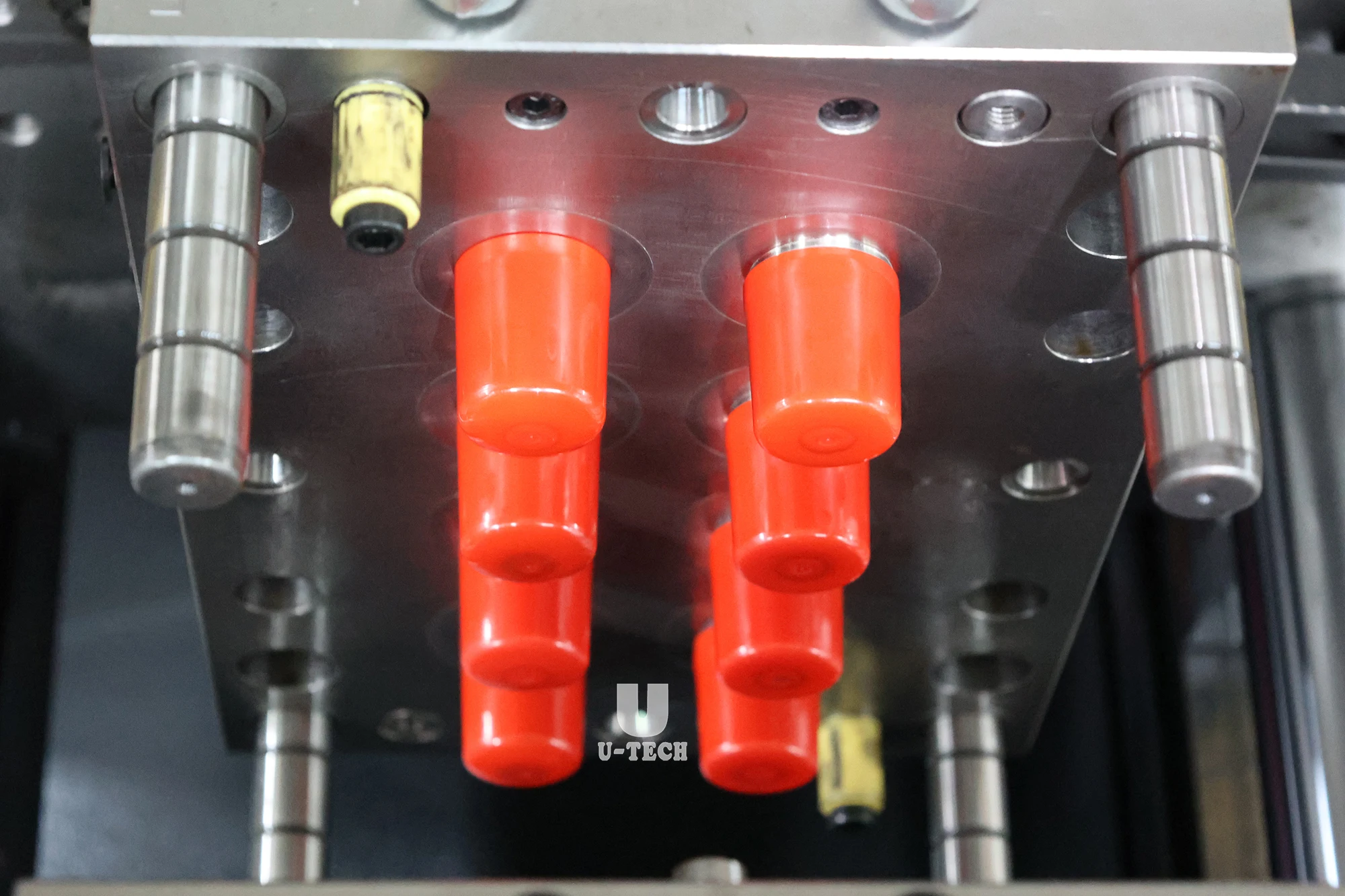

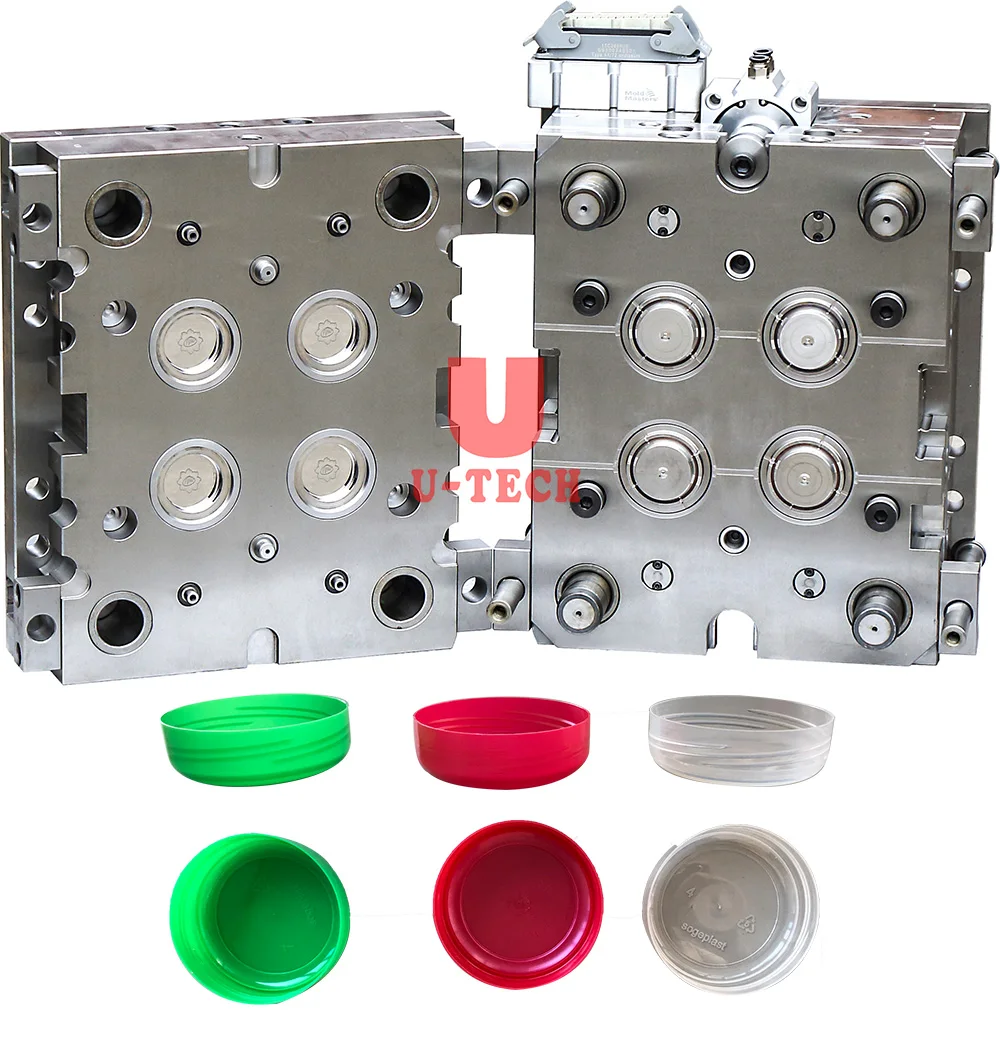

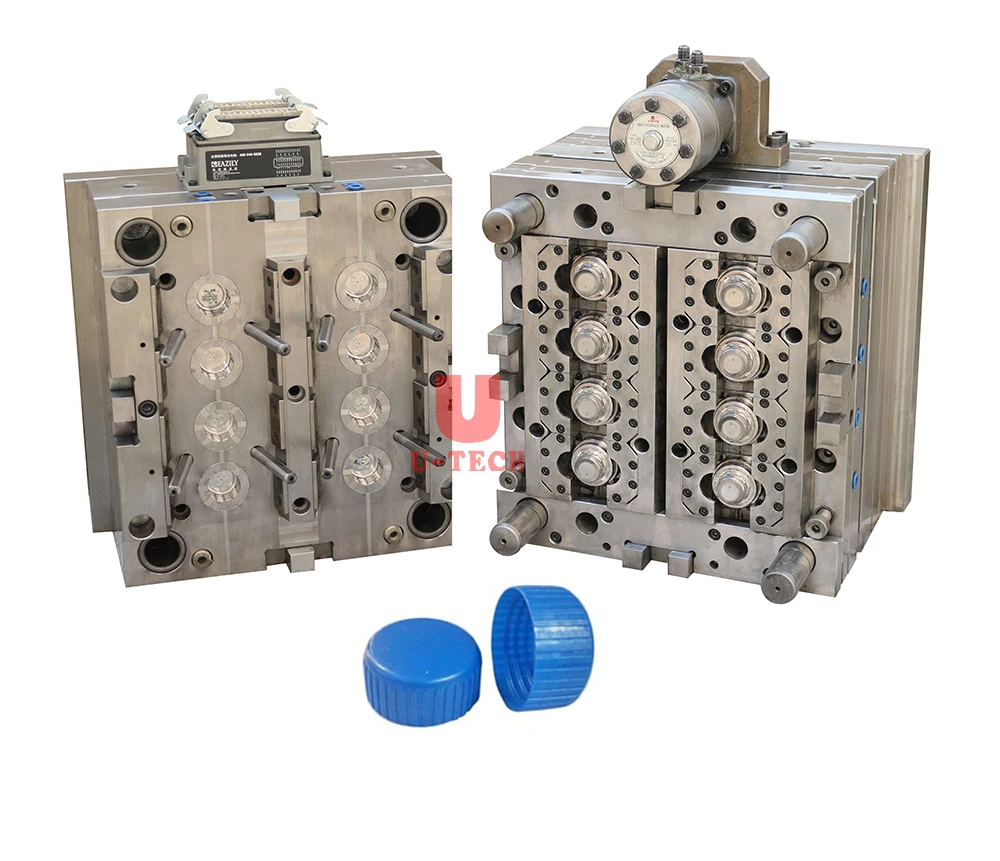

The molding process of general screw injection molding machine is: firstly, the granular or powdery plastic is added into the barrel, and the plastic becomes molten through the rotation of the screw and the heating of the barrel outer wall. Then, the machine closes the mold and moves the injection seat forward to make the nozzle close to the gate of the mold. Then, the injection cylinder is filled with pressure oil to make the screw move forward, so that the screw can be pushed forward with high pressure and speed After a certain period of time and pressure holding and cooling, the product can be opened to take out the product.

Zhangjiagang U Tech Machine Co.,Ltd

Professional manufacturer of beverage filling machine

E-mail:

Phone/Whatsapp:

+86-13962296786

- Home

- Products

- Water Filling Machine

- Carbonated Beverage Filling Machine

- Juice Tea Hot Filling Machine

- Glass Bottle Filling Machine

- Oil Filling Machine

- Can Filling Machine

- 5L/5Gallon water filling machine

- Piston filling machine

- Pretreatment System

- Labeling Machine

- Packing Machine

- Extrusion Blow Moulding Machine

- Jerrycan Blow Moulding Machine

- Plastic Bottle Blow Moulding Machine

- Drum & Barrels Blow Moulding Machine

- Toy & Playgound Parts Blow Moulding Machine

- Pallet ,Board &IBC Tank Blow Moulding Machine

- Traffic Barrer Blow Moulding Machine

- Automotive Parts Blow Moulding Machine

- Irregular-shaped products Blow Moulding Machine

- PET Bottle Blow Moulding Machine

- Injection Moulding Machine

- Spare Part

- Other auxiliary machine

- Beverage Filling Solutions

- Video

- Why Choose Us

- About Us

- Contact Us