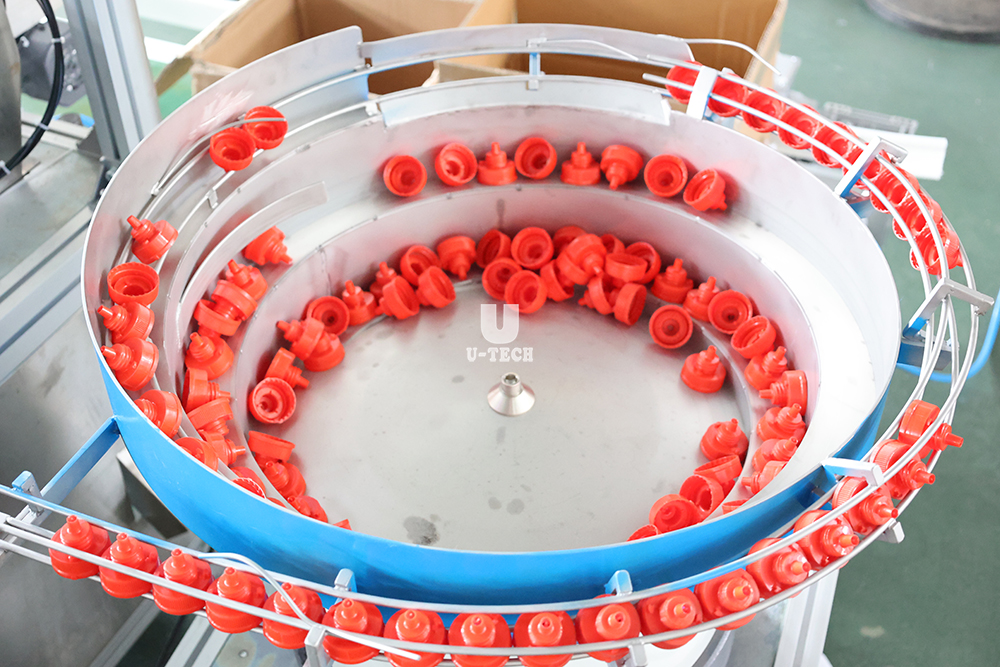

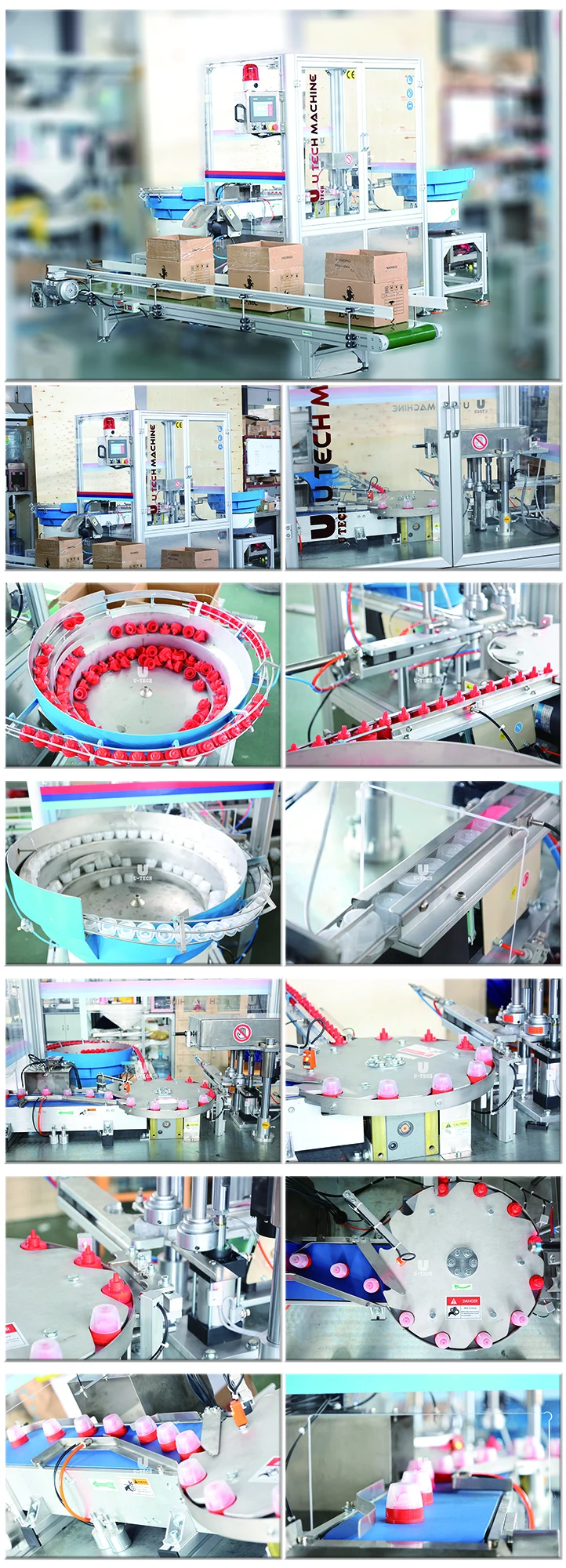

The cap assembly machine is a newly designed rotary multi-station high-speed assembly machine designed by our company. This machine adopts frequency conversion speed regulation, stable and reliable performance, and high degree of automation. It is an ideal plastic oil cap assembly equipment. It is suitable for various PET bottle caps of different sizes with threads. A combination of various complex lids, mainly composed of oil, pesticides, daily chemicals, beverages or water, etc., and other capping operations that need to replace manually.

Zhangjiagang U Tech Machine Co.,Ltd

Professional manufacturer of beverage filling machine

E-mail:

Phone/Whatsapp:

+86-13962296786

- Home

- Products

- Water Filling Machine

- Carbonated Beverage Filling Machine

- Juice Tea Hot Filling Machine

- Glass Bottle Filling Machine

- Oil Filling Machine

- Can Filling Machine

- 5L/5Gallon water filling machine

- Piston filling machine

- Pretreatment System

- Labeling Machine

- Packing Machine

- Extrusion Blow Moulding Machine

- Jerrycan Blow Moulding Machine

- Plastic Bottle Blow Moulding Machine

- Drum & Barrels Blow Moulding Machine

- Toy & Playgound Parts Blow Moulding Machine

- Pallet ,Board &IBC Tank Blow Moulding Machine

- Traffic Barrer Blow Moulding Machine

- Automotive Parts Blow Moulding Machine

- Irregular-shaped products Blow Moulding Machine

- PET Bottle Blow Moulding Machine

- Injection Moulding Machine

- Spare Part

- Other auxiliary machine

- Beverage Filling Solutions

- Video

- Why Choose Us

- About Us

- Contact Us